Products

Coated Glass

Super Low-E

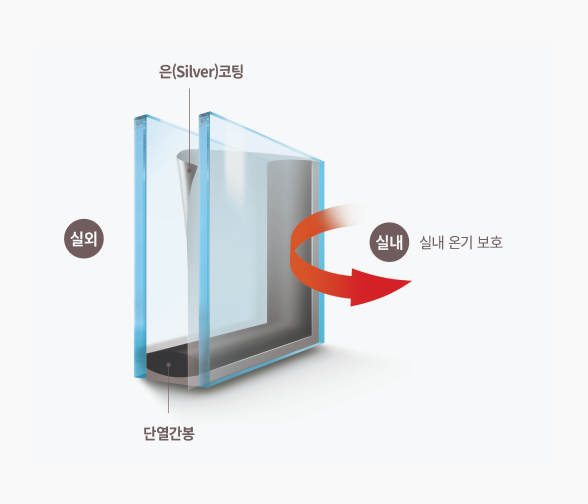

This single Low-E glass is a high-quality HANGLAS float glass with a coating of silver layer applied to one side of the glass. This is an energy-saving product that maintains indoor heat with its outstanding insulation.

Applications

• Residential, Small and mid-size buildings

Specifications

• Thickness: 5~8 mm

• Maximum dimensions: 3,353 mm × 6,096 mm

Key features

Precautions during coated glass installation

1. When the substrate used for reflective coating is coloured glass, thermal damage is a concern. Therefore, it must undergo tempering or heat-strengthening processing to increase its thermal stress resistance.

2. During product installation, the coated surface must be positioned facing the interior of the double-glazed unit or the building interior.

3. Protective shielding must be installed to prevent welding spatter from striking the coated surface.

4. When removing foreign matter from the coated surface, proceed in the following sequence:

1) Wipe with a soft, clean, dry cloth.

2) Wipe several times with a soft cloth dampened with clean water or a neutral detergent.

3) Remove moisture with a soft, dry cloth.

5. Cement, mortar, acids, alkaline substances (e.g., hydrochloric acid, ammonia solution), and solvents are harmful to the coated surface; ensure they do not come into contact.

6. Avoid direct contact with glass and metallic substances.

Precautions when processing coated glass

1. When handling, such as cutting or feeding into laminating lines, wear cotton gloves where possible.

2. When cutting, position the coated side facing upwards and ensure no glass cutting dust remains on the surface.

3. Do not mark the coated surface with chalk or marking pens and prevent oil contamination.

4. During cutting and processing, avoid touching the glass surface where possible. Take care to prevent saliva or moisture from splashing onto or adhering to the coated surface.

5. When cut Low-E glass will not be used for double glazing production on the same day, store it sealed in plastic with desiccant packs to prevent moisture ingress.

6. When cleaning Low-E glass, ensure only a soft brush is used.

7. When fabricating insulating glass units with low-E glass, edge stripping must be performed to enhance adhesion between the glass and sealant and to prevent the primary adhesive (butyl) from reacting with the low-E coating surface, which could compromise product durability. (NED coating is an exception.)

8. When fabricating double glazing with low-E glass, it is standard practice to position the coated surface on three sides. However, for low-E glass requiring simultaneous solar heat rejection, position the coated surface on two sides. Conversely, for double glazing where reflective glass is present on two sides, position the low-E glass's coated surface on three sides.

9. Reflective glass has a high solar heat gain coefficient, potentially causing thermal breakage. Therefore, thermal breakage assessment is required when selecting glass specifications.10. When laminating low-E glass, care must be taken as there is a risk of damage to the coated surface.